UPDATE: This project is now active for 6 days (until 8th of May 2018) on Kickstarter: https://www.kickstarter.com/projects/335524972/hydrogen-generator

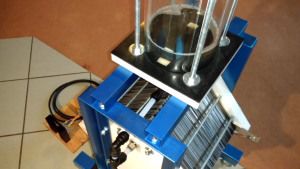

I have been researching HHO technology in my spare time for about ten years now. Many different cells have been built, many different driving techniques have been tried (DC, AC, Pulsed and Resonant). Now I have some experience in this field.

My current cell can produce around 10 LPM with input power around 3000 Watts. This cell is driven using rectified 230V AC.

To improve the gas production, now I come up with this new design. My target is to build a HHO cell that can run a 1.6 liter car engine. The gas production should be at least 30 liter/minute.

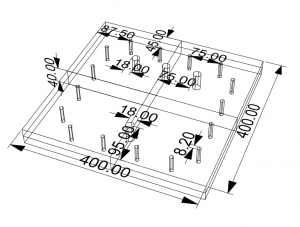

New cell specification:

- 320 neutral plates (material 1.4571/316Ti, thickness 1.5 mm)

- 2 terminal plates (material 1.4571/316Ti, thickness 3.0 mm)

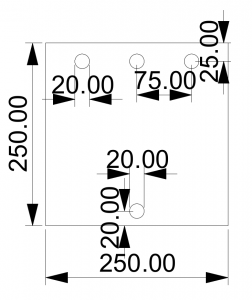

- 6 gas output outlets (12 mm pneumatic hose)

- 2 water inlets (12 mm pneumatic hose)

- Manometer (4 Bar)

- Pressure switch (adjustable, to avoid over pressure)

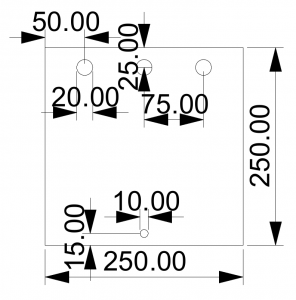

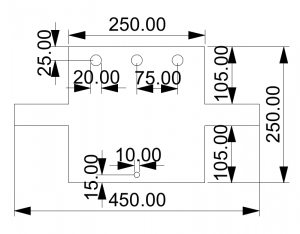

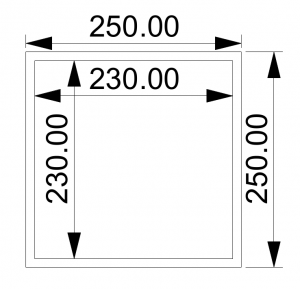

Following are the complete technical drawings of my new design (all measurements are in millimeter).

Gasket EPDM between metal plates (thickness 1 mm, 321 pcs.)

Gasket EPDM between metal plates (thickness 1 mm, 321 pcs.)

Gasket EPDM for end plates (thickness 1 mm, 2 pcs.)

Gasket EPDM for end plates (thickness 1 mm, 2 pcs.)

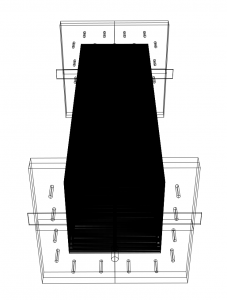

The complete cell should look like this

The complete cell should look like this

I hope that I can build this cell as soon as possible.